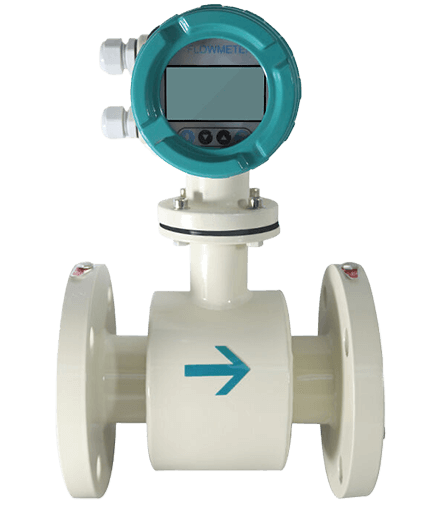

The OMF Series electromagnetic flowmeters measure flow by applying electromagnetic induction. As conductive liquids pass through, a magnetic field induces a voltage proportional to flow rate. The series flowmeter offers high accuracy, reliability, and durability, with no moving parts, making them ideal for a wide range of industrial applications.

The OMF Series electromagnetic flow meter is a kind of flow meter made by adopting Faraday law of electromagnetic induction. This product is made by adopting the latest technology of modern electromagnetic flow meter with following features:

The measurement is not affected by the change of liquid density, viscosity, temperature, pressure and conductivity.

There is no component which may impede flowing in the measuring tube, no pressure loss, straight pipe section shall be relatively low.

The inside nominal diameter DN3- DN3000. Several selections are available for the sensor lining and electrode material.

The converter adopts new excitation method, and features low power consumption, stable zero point and high precision.

The converter can be formed in integrated or separated type with the sensor.

The converter adopts 16-digit high performance microprocessor, 3-line 128×64 LCD lattice English character display, and features convenient parameters setting, reliable programing.

The flow meter is the bidirectional measurement system and is installed with three integrators to record the total volume: forward total volume, reversed total volume and total difference; it can display forward flow and reverse flow volume, additionally, it can output: current, pulse, digital communication.

The converter adopts surface mounting technology (SMT) with the functions of self-inspection and self-diagnosis.

The rubber and polyurethane lining sensor adopt intrinsic immersion structure.

The explosion-proof instrument can be used for corresponding explosion-proof site.

The OMF series Electromagnetic flowmeters are widely used in various industries due to their high accuracy, reliability, and the ability to measure flow without moving parts. They are best suited for measuring the flow of conductive liquids.

Water and Wastewater Treatment: Water Distribution, Wastewater Management

Marine and Shipping Industry: Ballast Water Management

Pharmaceutical and Biotechnology: Pharmaceutical Manufacturing, Biotechnology Processes

Food and Beverage Industry: Beverage Production, Dairy and Other Liquids

Power Generation: Cooling Water Monitoring, Feedwater Monitoring

Chemical and Petrochemical Industries: Chemical Processing, Petrochemicals

Mining and Mineral Processing: Slurry Measurement, Chemical Leaching Processes

Pulp and Paper Industry: Pulp Processing, Paper Production

Irrigation and Agriculture: Irrigation Systems monitoring

|

Name |

Specifications |

|||||||

|

Nominal Diameter |

3mm-3000mm |

|||||||

|

Upper Flow Limit |

15m/s |

|||||||

|

Accuracy |

±0.5% of the indicating value |

|||||||

|

Liquid conductivity |

≥5uS/cm |

|||||||

|

Pressure Rating |

4.0MPa |

1.6MPa |

1.0MPa |

0.6MPa |

6.3MPa |

10MPa |

||

|

DN3- DN700 |

DN15- DN1600 |

DN15- DN2200 |

DN700- DN3000 |

DN15- DN500 |

For special orders |

|||

|

Liner Material |

PTFE, Rubber, PFA, F46, Ceramic |

|||||||

|

Environment Temperature |

Sensor: -25℃~+60℃ Converter and Compact type: -10℃~+60℃; |

|||||||

|

Maximum Liquid Temperature |

Compact Type |

80℃ |

||||||

|

Split Type |

Rubber |

120℃ |

||||||

|

PU |

100℃ |

|||||||

|

PTFE |

150℃ |

|||||||

|

F46 |

||||||||

|

PFA |

||||||||

|

Electrode Material |

SS 316L, Hastelloy C, Hastelloy B, Titanium, Tantalum, Platinum-iridium alloy, SS316 coated with WC |

|||||||

|

Housing Protection |

IP65, IP67, IP68 |

|||||||

|

Power Supply |

DC 19-40V; AC85-250V; Lithium Battery |

|||||||

|

Process Connection |

Flange: GB, ASME, DIN, GOST, JIS Thread: G Thread, M Thread Wafer: Inline Wafer Clamp: Tri-Clamp |

|||||||

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: