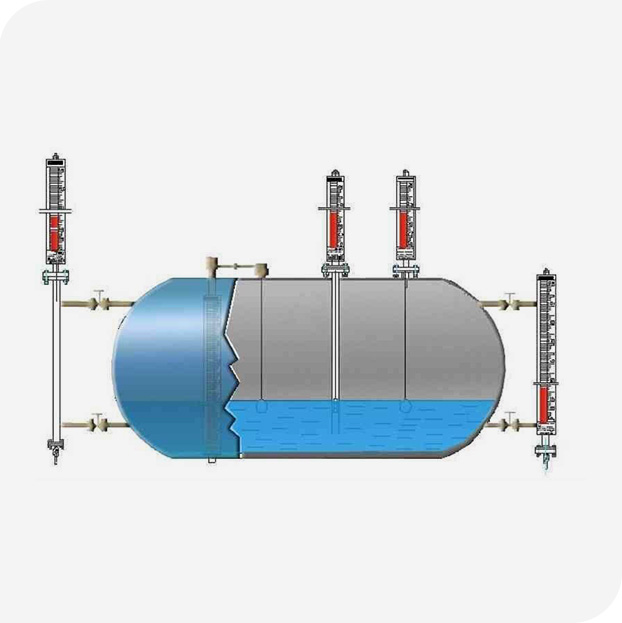

The OMLI series magnetic flap level indicator uses a magnetic float to detect liquid levels. As the float moves, it flips magnetic flaps, indicating the level. Advantages include high reliability, no power consumption, easy installation, and suitability for various liquid types, ensuring accurate, continuous level measurement. When paired with electronics, it can output signals and integrate into automation systems.

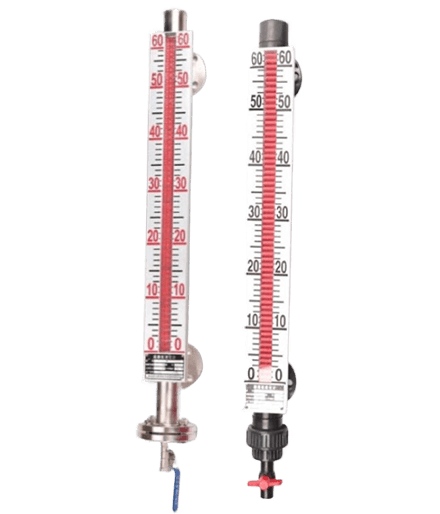

The OMLI series magnetic flap level indicator is composed of three parts: the float, the vertical pipe assembly, and the indicator. The float rises or falls within the vertical pipe assembly according to the liquid level, causing the color of the indicator outside the vertical pipe to change (red for liquid, white for gas) through magnetic coupling, thus indicating the height of the liquid level.

The OMLI series magnetic flap level indicator uses the principles of buoyancy and magnetic coupling to linearly transmit changes in liquid level to the indicator, clearly showing the liquid level height. The indicator is completely isolated from the storage tank, ensuring absolute safety during use. This level indicator can also be equipped with level alarm switches and level remote transmitters. The alarm switch can control the upper and lower levels, limit alarms, and interlocks. The remote transmitter can convert the level change into a 4-20mA DC output for remote level indication, monitoring, control, and recording.

The OMLI series magnetic flap level indicator is suitable for measurements in different tanks and silos, and it is suitable for various industries and environments.

Level monitoring in water treatment facilities

Sludge level detection in sedimentation tanks

Fuel oil storage tanks Boiler water level monitoring

Chemical process tanks

Oil storage tanks

|

Name |

Specifications |

|||||||

|

Measurement range: |

0 ~ 12m |

|||||||

|

Indication accuracy: |

±10mm |

|||||||

|

Working pressure: |

1.0 ~ 6.4MPa |

|||||||

|

Operating temperature: |

-20 ~ 350℃ |

|||||||

|

Medium density: |

≥0.45g/cm³ |

|||||||

|

Medium density difference: |

≥0.15g/cm³ (interface measurement) |

|||||||

|

Medium viscosity: |

≤0.15 Pa.S |

|||||||

|

Wetted materials: |

1Cr18Ni9Ti, SUS304, SUS316, SUS316L, Titanium, PVC, Fiberglass |

|||||||

|

Flange connection: |

Pressure ≤2.5MPa JB/T81-94 PN2.5 DN20, Pressure ≥2.5MPa JB/T82.2-94 PN6.4 DN20 (or as per customer requirement) |

|||||||

|

Drain connection: |

ZG1/2" (internal) |

|||||||

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: