The OGFM Series Oval Gear Flow Meter measures flow by using two oval gears that rotate as fluid passes through. The rotation is proportional to the flow rate. Advantages include high accuracy, low maintenance, compact design, and suitability for a wide range of liquids, including viscous fluids.

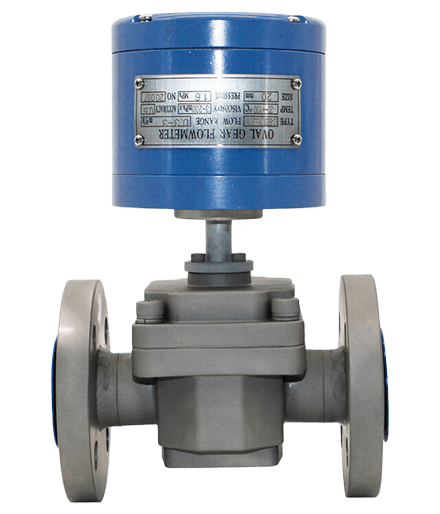

The OGFM Series Oval Gear Flow Meter is a positive displacement flow meter designed for precise measurement and control of liquids within pipelines. It consists of a robust meter shell, oval gear rotors, and a converter. This instrument is suitable for both continuous and batch metering applications, offering a wide measurement range and exceptional accuracy. Notably, it operates effectively without the need for straight pipe runs and demonstrates high viscosity adaptability. The OGFM Series excels in measuring high-temperature and high-viscosity liquids, making it ideal for various industries, including crude oil, chemicals, chemical fibers, food and beverage, pharmaceuticals, scientific research, and military applications.

High Accuracy: Delivers precise measurements across a large flow range with excellent repeatability.

Simple Structure: Designed for reliable operation with minimal complexity.

Wide Viscosity Range: Effectively measures fluids with varying viscosities, making it suitable for high-viscosity mediums.

Unaffected Flow State: Measurement accuracy remains consistent regardless of flow conditions; no straight pipe runs are required upstream or downstream of the flow meter.

The OGFM Series Oval Gear Flow Meter is installed in a metering pipeline, utilizing a pair of oval gear mechanisms housed within a sealed cavity formed by the upper and lower covers. As the gears rotate, they facilitate liquid flow measurement. When liquid enters the flow meter, pressure from the inlet and outlet promotes the rotation of the differential gears. This constant measurement allows the liquid to be delivered to the outlet, with the elliptical gears displacing a volume of liquid equivalent to four times the measured volume with each complete revolution.

Oil field (crude oil)

Oil Pipelines (refined oil)

Custody transfer of refined oils or edible oils

Refinery, Chemical plants

Bulk loading of tanks, ships, planes and trucks

Measurement or monitoring of the production process of beverage and alcohol

|

Name |

Specifications |

|||||||

|

Model |

OGFM |

|||||||

|

Transmitter Type |

Pointer Display; Pointer with zero returning; Pointer displays with Output; LCD |

|||||||

|

Medium |

Fuel Oil; Petroleum; Petroleum Products; Vegetable Oil; Food; Chemicals |

|||||||

|

Accuracy |

±0.2%; ±0.5%; |

|||||||

|

Nominal Diameter |

DN8~DN200 mm |

|||||||

|

Nominal Pressure |

PN1.6~6.3MPa; |

|||||||

|

Medium Temperature |

-10 °C~280 °C |

|||||||

|

Medium Viscosity |

2~3000mPa•s |

|||||||

|

Power Supply |

12V.DC; 24V.DC |

|||||||

|

Output Signal |

Pulse; 4~20mA.DC; RS485 |

|||||||

|

Display |

Accumulative Flow, Single Measurement (Mechanical Dial); Remote transmission of total and instantaneous flow |

|||||||

|

Error Adjustment |

Changing Gear Adjustment |

|||||||

|

Level Of Protection |

IP65 |

|||||||

|

Explosion Proof |

Flame-proof Type, ExdIIBT4 |

|||||||

|

Ambient Temperature |

-20~55°C |

|||||||

|

Sensor Material |

Cast Iron; Cast Steel; Stainless Steel |

|||||||

|

Sensor Connection |

Flange, Thread, Sanitary tri-clamp |

|||||||

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: