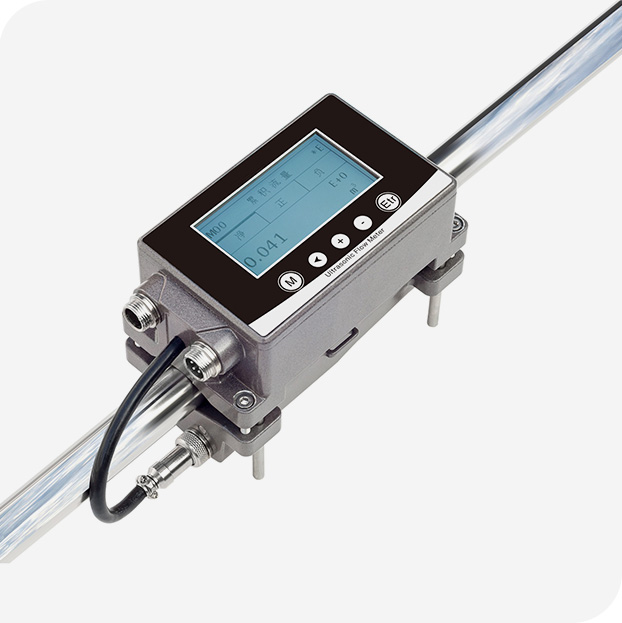

The OUF-FLEX series quick clamp small pipe ultrasonic flowmeter uses ultrasonic waves to measure flow in small pipes. It clamps onto the outside of the pipe, offering a non-invasive solution. Advantages include easy installation, no disruption to flow, high accuracy, and suitability for small-diameter pipes, making it ideal for various industries.

The OUF-FLEX series quick clamp small pipe ultrasonic flow meters is specially designed for small pipe flow measurements. It utilizes ultrasound time differential theory and is equipped with the latest industrial level PFGA, it has extremely improved signal sampling frequency and bubble tolerance rate. The quick clamp small pipe ultrasonic flowmeter could be installed without cutting the pipe and simply clamp it, connect the flowmeter to power, then you will be able to read the measurements directly through the large size LCD display.

Easily and friendly for installation and operation. It only takes a few minutes, from the start of installation to reading from the flow meter.

Adopts a new external clamp design, which could measure the flow rate without touch the measurement medium. Compared with other traditional flow meter, this could avoid pressure loss or media contamination problems.

As the advantage of a clamp on flow meter, no need to cut off the pipe or long time stop the equipment, save the cost of time and labor costs.

A variety of modes are available for setting and flexibility. One set is universal for all pipe size in the measuring range, and suitable for many kinds of metal and plastic pipes

256*128 LCD display. Display a variety of information.

It is optional to become an ultrasonic cooling (heat) meter/ btu meter/ energy meter to realize the monitoring and measurement of energy.

The OUF-FLEX series quick clamp small pipe ultrasonic flow meters can be applied to a wide range of pipe flow measurements. Applicable liquids include pure liquids as well as liquid with small quantity of tiny particles.

Sewage with small particle content.

Oil (crude oil, lubricating oil, diesel oil, fuel oil, etc.).

Chemicals (alcohol, acids, etc.).

Beverage

Ultra-pure liquids.

Solvents and other liquids

|

Name |

Specifications |

|||||||

|

Pipe Material |

Metal /PVC, PP or PVDF rigid plastic pipe |

|||||||

|

Liquid Type |

Water/other liquid (Single liquid medium without solid particles or impurities) |

|||||||

|

Temperature range |

0-75℃ (No freezing on the surface) |

|||||||

|

Low velocity cut off value (Default by factory) |

0.1m/s |

|||||||

|

Display |

256*128, LCD |

|||||||

|

Response time |

0.5-60s |

|||||||

|

Accuracy |

±2%, (±1% after calibration) |

|||||||

|

Data Storage Period |

300ms |

|||||||

|

Memory for data backup |

EEPROM (Data storage over 10 years, data read/write frequency: over 1 million times) |

|||||||

|

Power and I/O connection |

M12 type aviation plug |

|||||||

|

Output |

4-20mA |

|||||||

|

Communication |

Modbus RS485 |

|||||||

|

(Options for Output) |

OCT (pulse output)/ One relay alarm (please contact the factory) |

|||||||

|

Power Supply |

10-24V DC |

|||||||

|

Power Consumption |

<3W |

|||||||

|

Protective Circuit |

Power reverse connection protection, Power surge protection, |

|||||||

|

Output short circuit protection, Output surge protection |

||||||||

|

Enclosure Protection Class |

IP65 |

|||||||

|

Environmental Temperature |

-10 to 60°C (No freezing) |

|||||||

|

Relative Humidity |

35 to 85% RH (No condensation) |

|||||||

|

Vibration Resistance |

10 to 55 Hz |

|||||||

|

double amplitude 1.5 mm, 2 hours in each XYZ axis |

||||||||

|

Impact Resistant |

100 m/s2 16 ms pulse, 1000 times each for X, Y and Z axis |

|||||||

|

Main Material |

Aluminum, Industrial Plastics |

|||||||

|

Cable Length |

2m(standard), PT1000 sensor standard cable length is 9m |

|||||||

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: