The OTGM series thermal gas mass flowmeter measures gas flow by detecting heat transfer between heated sensors and the gas. It offers high accuracy, fast response, and direct mass flow measurement. Advantages include low maintenance, wide application range, and suitability for various gases, including air, natural gas, and nitrogen.

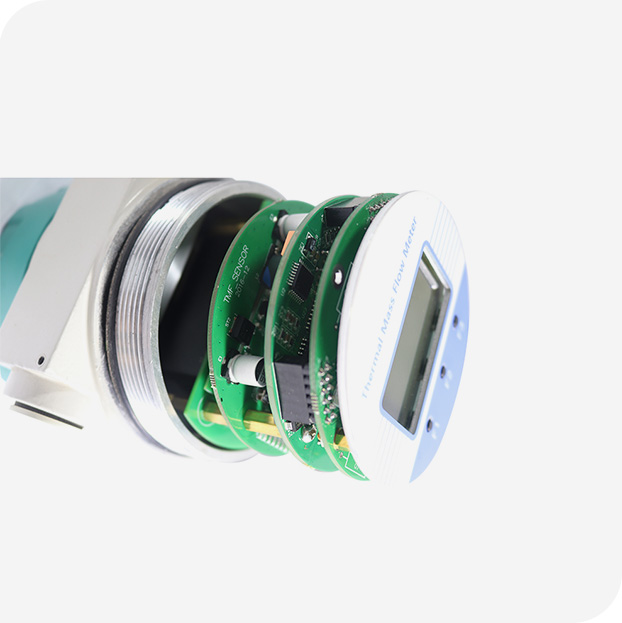

The OTGM series thermal gas mass flow meter is designed based on thermal dispersion and adopts method of constant differential temperature to measuring gas flow.

Due to the sensor temperature is always 30℃ higher than the medium temperature (environment temperature), and the meter adopts method of constant differential temperature, therefore the meter does not need to do temperature and pressure compensation.

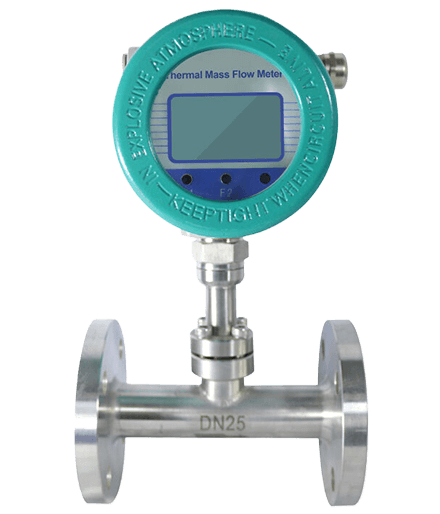

It has advantages of small size, easy installation, high reliability and high accuracy. It can detect the temperature, pressure and flow of the measured gas, can automatically track and compensate the flow, and display the cumulative volume of the gas in the standard state (Pb=101.325kPa, Tb=293.15K).

Measuring the mass flow or volume flow of gas.

Do not need to do temperature and pressure compensation in principle with accurate measurement and easy operation.

Wide range: 0.5Nm/s~100Nm/s for gas. The meter also can be used for gas leak detection.

Good vibration resistance and long service life. No moving parts and pressure sensor in transducer, no vibration influence on the measurement accuracy.

Easy installation and maintenance. If the conditions on site are permissible, the meter can achieve a hot-tapped installation and maintenance. (Special order of custom-made).

Digital design, high accuracy and stability.

Configuring with RS485 or HART interface to realize factory automation and integration.

The OTGM series thermal gas mass flow meter is expertly engineered for diverse applications across various industries, providing accurate and reliable measurement of gas flow. Key applications include:

Multi-Component Gas Measurement: Effectively measuring gases such as oxygen, nitrogen, hydrogen, chlorine, aeration, and fuel gas.

Blast Furnace and Coke Oven Gas: Precise measurement of blast furnace gas and coke oven gas to optimize operational efficiency.

Biogas and Water Treatment: Monitoring biogas levels, aeration processes, and chlorine in water treatment applications.

Compressed Air Systems: Reliable and accurate measurement of compressed air flow.

Natural and Liquefied Gas: Flow measurement for natural gas, liquefied gas, torch gas, and other gaseous substances.

Power Generation: Measurement of primary and secondary air flow in power plant blast furnaces.

Underground Ventilation: Accurate airflow measurement in underground ventilation and exhaust systems.

Gas Process Applications: Monitoring air flow in a variety of gas processing operations.

ICement and Glass Production: Ensuring precise gas flow measurement in the production processes of cement and glass manufacturing.

Solvent Recovery Systems: Effective gas flow measurement in solvent recovery applications.

Semiconductor Manufacturing: Accurate gas flow measurement in semiconductor chip production processes.

Brewery Production: Monitoring carbon dioxide gas flow during beer production for quality assurance.

HVAC Systems: Reliable measurement of gas flow rates in heating, ventilation, and air conditioning systems.

|

Name |

Specifications |

|||||||

|

Name |

OTGM Series Thermal Mass Flowmeter |

|||||||

|

Construction |

Insertion Type |

Inline Type |

||||||

|

Size |

DN32mm and above |

DN15-200mm |

||||||

|

Medium |

Various Gases (Except acetylene) |

|||||||

|

Accuracy |

±1.0%~±2.5% |

|||||||

|

Process Connections |

Insertion |

Flanged |

||||||

|

Pressure Rating |

PN16 |

PN40 |

||||||

|

Medium Temperature |

≤120℃ |

|||||||

|

Ambient Temperature |

-20℃~45℃ |

|||||||

|

Power Supply |

220VAC 24VDC |

|||||||

|

Output |

Pulse 4 ~ 20mA RS485 HART |

|||||||

|

Flange Material |

316 Stainless Steel 304 Stainless Steel Carbon Steel |

|||||||

|

Body Material |

304 Stainless Steel 316 Stainless Steel Carbon Steel |

|||||||

|

Display |

LCD back light display. Showing: Temperature; Mass Flow; Volume Flow; Totalizer; Time |

|||||||

|

Response Time |

1S |

|||||||

|

Measurement Range |

0.1~120Nm/s |

|||||||

|

Enclosure Protection Class |

IP65 |

|||||||

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: