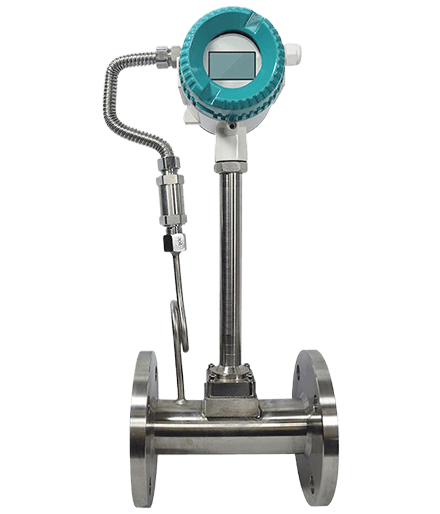

The OVF series vortex flowmeters measure flow by detecting vortices shed behind a bluff body in the fluid stream. The frequency of vortex formation correlates with flow rate. Advantages include high accuracy, low maintenance, and suitability for various liquids, gases, and steams, even in harsh environments with high temperature or pressure.

The OVF series intelligent vortex flow measures flow rate by detecting the frequency at which alternating vortices are shed from a bluff body inserted into the flow steam. This principle of measurement is known as Von Karman’s vortex street principle. Our OVF series intelligent vortex flow meter provides accurate standard volumetric and mass flow measurement of steam, gases and liquids as an all-in-one solution with integrated temperature and pressure compensation.

No moveable mechanical components, corrosion resistance, stable and reliable performance.

10-section correction with functions of self-diagnosis of trouble shooting and alarm.

Output signal 4~20mA, frequency, RS485, HART interface.

16-digit computer chip with high integration, small size, high performance and strong functions.

On-site display, indicating instant flow rate, total amount and flow signal frequency.

Low power consumption, optional built-in battery power supply and standard external power supply.

Integrated temperature and pressure sensor, real-time correction measurement medium density, high accuracy.

Optional for temperature and pressure compensation to enhance accuracy for gas, steam and other compressible media measurement.

Excellent ability of anti-interference and anti-vibration.

Wide temperature range: -40 ℃ ~ 350 ℃ for selection.

The OVF Series Vortex flowmeter is widely used in petroleum, chemical, metallurgical, thermal, textile, paper and other industries to monitoring and control flows of superheated steam, saturated steam, compressed air and general gases (oxygen, nitrogen, argon, hydrogen, natural gas, gas, etc.) water, liquid and other media.

Chemical and petrochemical: The OVF series Vortex flow meters are used to monitor the flow of chemicals, liquids, or gases in production processes.

Food and beverage: The OVF series vortex flow meters are used to measure the flow of liquid ingredients in beverage and food processing.

Energy: The vortex flow meters are used to monitor the flow of hot water, steam, and compressed air.

|

Name |

Specifications |

|||||||

|

Item |

Parameter |

|||||||

|

Measuring Fluid |

Steam, Gas, Liquid (Including water, oil, corrosive solutions) |

|||||||

|

Working Environment Temperature: |

-40-350℃; |

|||||||

|

Power Supply |

3.6V Lithium Battery; 24VDC; 220VAC |

|||||||

|

Pressure Rating |

1.6MPa; 2.5MPa; 4.0MPa; 6.3MPa |

|||||||

|

Pipe Material |

SS316; SS304; Carbon Steel |

|||||||

|

Enclosure Protection Class |

IP65; IP68 |

|||||||

|

Measurement Accuracy |

Liquid: ±0.5% Gas/Steam: ±1.0%; ±1.5% |

|||||||

|

Output Signal |

Analog, Pulse, RS-485 Modbus; HART |

|||||||

|

Nominal Diameter |

Inline Type: DN20~DN350 Insertion Type: DN300-1200 |

|||||||

|

Process Connection |

Flange, Wafer, Insertion |

|||||||

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: